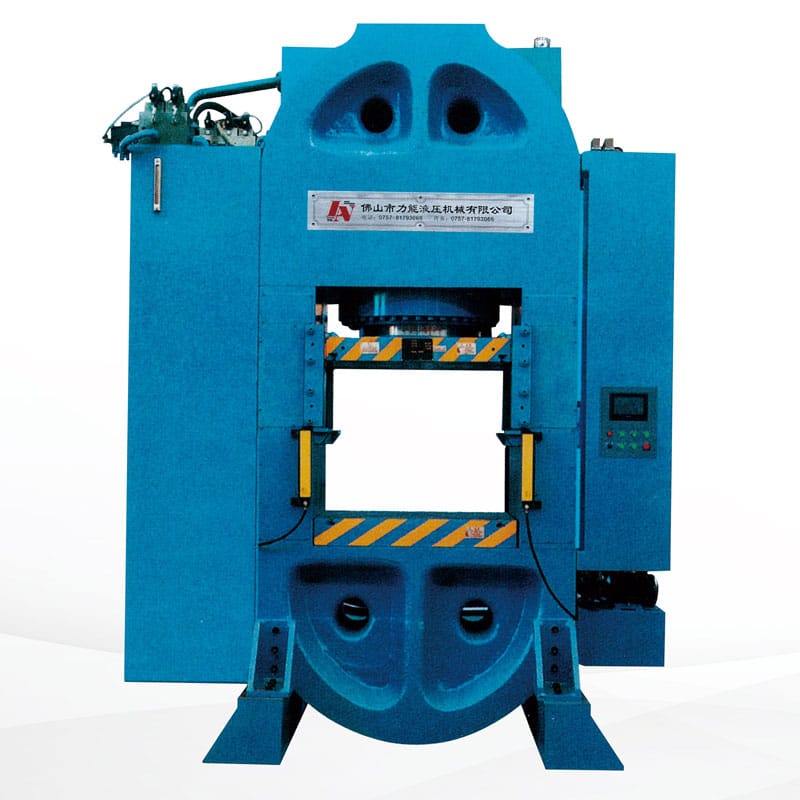

LN34-R series steel wire winding hydraulic press

The LN34-R series steel wire winding hydraulic press is suitable for high-density corrugated shallow stretching and non-metallic sheetmetal forming such as the forming of plate heat exchanger plates, hydrogen production electrode plates, silicon carbide plate, etc lt is also suitable for extrusion thinning forming of imitation die-casting aluminum pots, composite pot bottom forming, hardware embossing, compound mold forming, and other processes Functions such as pressure maintaining and material returning can be added according to customer needs.

Product Category

Product Feature

- The frame is wrapped with pre-stressed steel wire into a whole, ensuring safe and reliable use;

- Good fatigue strength and long service life;

- The frame is lightweight, effectively reducing stress concentration and significantly improving load-bearing capacity;

- Automatic counting function;

- The main sealing components are imported products, with a long service life;

- The key electrical components adopt well-known brands from Europe, America, and Japan, with high working reliability;

- The hydraulic components are selected from internationally renowned brands to ensure good performance;

- The surface of the guide pillar and piston rod are treated with medium frequency and plated with hard chromium;

- Equipped with infrared protection device for safer operation;

- It can be configured with upper feeding or lower returning according to customer needs.

Technical Parameter

| Project | Unit | Parameter | |||||||

| LN34R-2500 | LN34R-3000 | LN34R-3500 | LN34R-4000 | LN34R-4500 | LN34R-5000 | ||||

| Main cylinder nominal force | KN | 25000 | 30000 | 35000 | 40000 | 45000 | 50000 | ||

| Effective area of workbench | About | mm | 960 | 1050 | 1120 | 1220 | 1260 | 1330 | |

| Around | mm | 960 | 1050 | 1120 | 1220 | 1260 | 1330 | ||

| Maximum working pressure of the main cylinder | Mpa | 71 | 70 | 70 | 70 | 71 | 70 | ||

| Rated working pressure of hydraulic system | Mpa | 25 | 25 | 25 | 25 | 25 | 25 | ||

| Maximum working stroke of the main oil cylinder | mm | 200 | 200 | 200 | 200 | 200 | 200 | ||

| Maximum enclosed height | mm | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | ||

| Main cylinder speed | Ejection | mm/s | 86 | 94 | 60 | 60 | 75 | 75 | |

| Suppress | mm/s | 0.27 | 0.3 | 0.33 | 0.29 | 0.32 | 0.29 | ||

| Return | mm/s | 180 | 170 | 100 | 100 | 125 | 125 | ||

| Total power | KW | 27 | 37 | 45 | 45 | 55 | 55 | ||

| Overall dimensions of the main engine (excluding fuel tank) | About | mm | 1525 | 1675 | 1850 | 1926 | 1998 | 2106 | |

| Around | mm | 1260 | 1350 | 1420 | 1520 | 1560 | 1630 | ||

| Height | mm | 3807 | 3955 | 4280 | 4218 | 4314 | 4368 | ||